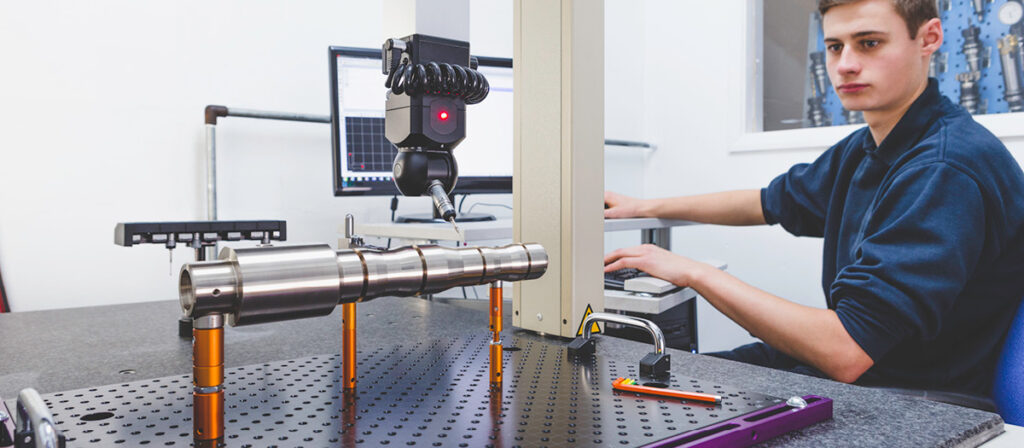

The summer of 2020 may have looked different than what we’re used to in many respects, but one initiative that was not derailed by the pandemic was MD MEP’s annual Manufacturing Summer Internship Program. Now in its fifth year, this program helps expose young talent to valuable career opportunities within Maryland’s manufacturing community by matching college students with local manufacturers to gain real-life experience in their chosen field of study.

This year, 15 students were placed in summer positions at 10 local companies and given their own unique work experience to enhance their studies and cultivate their skillsets. Here’s a sampling of the broad array of projects our interns completed this summer:

STULZ

- Aziz helped ensure STULZ’s employees stayed safe while they worked by maintaining the company’s personal protective equipment program and helping to proof test custom rigging equipment. He also helped the company prepare for a Corporate Social Responsibilities audit and performed noise exposure studies.

- Chris provided valuable assistance to STULZ engineers, assisting with both setting up and documenting a new work center to process extruded aluminum framing using CNC equipment, and changing manufacturing workflows to improve warehouse and production material harmonization.

INPRO Technologies, Inc.

- Adam had the opportunity to contribute significantly to the AP2020 project, in which INPRO designed, constructed, and delivered a UV curing machine that instantly cures coatings applied to clear polycarbonate sheets to make them more scratch resistant. Adam helped finish all the engineering drawings and conceptualize and design critical elements that were added late in the design, including a safety rail to prevent the system from tipping over. He was instrumental in finishing the design and was a primary contributor to the final assembly and fabrication of the whole system.

TRX Systems

- Robert created a dashboard for the new TRX Micro-Tracer product that will help people get back to work safely during the COVID-19 pandemic by allowing administrators to automate contact tracing and evaluate trends in contact and transmission. Robert was tasked with coming up with new ways to display the data and worked with a small team to implement his ideas into the dashboard demo.

- Jacob’s internship focused on designing, developing and assembling an advanced military positioning system called DAPS. He applied planning techniques to ensure the device could be assembled and programmed in a straightforward manner.

Working closely with senior engineers, he also helped implement advanced mechanics to enhance the product, including an internal clock to aid in detecting a signal with low integrity. Jacob learned many valuable skills while contributing to the development of a project that will benefit the company.

Sisu Global

- Haniya was a valued member of Sisu Global’s PR and marketing team this summer, as not all manufacturing career opportunities are on the production floor. She helped to develop and craft messaging for a number of initiatives, including social media campaigns, an awards acceptance speech, a training presentation on diversity and inclusion, outreach messages for investors and partners, press releases and more. Haniya’s supervisor reports that she truly went above and beyond with every project and task she was given, exceeded expectations at every turn and provided true value to the company.

ACDi

- Camila was tasked with working on engineering process controls and one-piece flow methodologies for a high quantity build. Her work culminated in the creation of a build playbook for a high quantity build and the setup of a one-piece flow assembly line that significantly increased daily production and improved original output using batch production techniques. In addition, Camila used her J-STD-001G certification to train and certify four employees at ACDi’s Frederick facility and 10 employees at the company’s North Carolina facility. She also planned and conducted the onboarding training for the newest ACDi junior manufacturing engineer.

Miltec UV

- Julie played a significant role in the development of a new HPI XY Mapper system. She researched the necessary software and wrote three programs to accommodate different testing scenarios. She helped test the new system and updated its 3D model to include light shielding, a laptop computer and electrical control box. She also conducted a review meeting with the engineering department and documented changes that were needed in the design. She also updated work instruction and trained employees on the new system.

We’d like to thank all the companies mentioned above, as well as EFI Group, Potomac Photonics, Aidar Health, and Stress Indicators for going above and beyond this summer to provide safe environments for our interns to gain this invaluable work experience. And congratulations to our interns on jobs well done – these 15 young individuals exemplify the promising future of Maryland’s manufacturing workforce. If your Maryland manufacturing company would like to offer internship opportunities to rising college juniors, seniors and graduate students, we would love to have you as part of our next Summer Internship Program! To inquire, please contact Kerry Wells at kwells@mdmep.org.